Geometry

Circular and other channel cross-sections

Flexibility

Easy to customize. Reduce your connectors, expand your geometries.

Clarity

Freeform, optical grade surface roughness

Speed and Volume

Rapid prototyping to Mass manufacture.

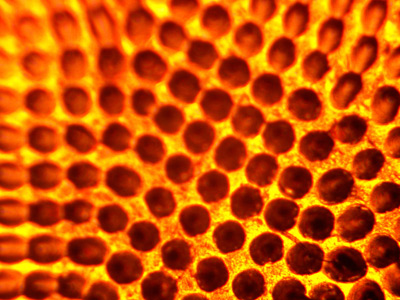

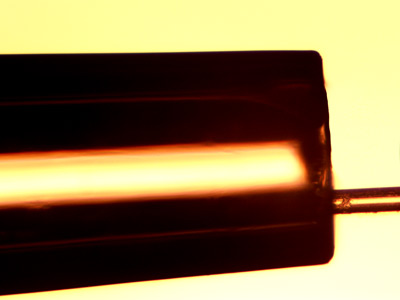

Circular Channels

Look around you. Fluids don't flow naturally in rectangular and semi-circular shaped channels. Channel shape and surface roughness impact flow and detection. That is why Hummingbird Nano created the world's first ultra-smooth, circular channel microfluidic chips in a single solid form.

No Bonding

Let's face it, bonding complicates manufacturing. Because Hummingbird Nano uses a solid form and not two separate chip lids, no bonding is necessary

No Expensive Tooling

Commercialization is much simpler and easier because there is no expensive tooling involved.

Reduce Risk of Transferring Prototypes to Manufacturing

Because Hummingbird Nano uses the same process for prototyping and high volume production, you can get to market quicker and without the worry that your prototype is not suitable for manufacturing.

What Does It All Mean?

- Greater chip success

- Less waste of expensive reagents

- Less time cleaning

Primary Applications

- Microfluidic Chips

- Micro Heat Transfer Systems